GD&T includes a set of symbols that stand for various kinds of geometric control, which are vital for guaranteeing component performance and manufacturability. Recognizing GD&T symbols and guidelines can considerably improve the quality of engineering illustrations and add to smoother manufacturing procedures.

To start with, GD&T symbols are standard and specified in the ASME Y14.5 criterion, which indicates they have universal approval in engineering disciplines. Each symbol shares details info concerning the tolerance put on an attribute. Symbols for monotony, straightness, circularity, and cylindricality portray the allowed inconsistency from the suitable geometric kind. Monotony, represented by a two-dimensional sign, guarantees that a surface area is uniformly level within specified limitations, which is essential for surface areas that require to mate or secure. Understanding and using these symbols accurately can assist stop inequalities and assembly issues, enhancing item integrity.

Discover GD&T symbols and guidelines the value of Geometric Dimensioning and Tolerancing (GD&T) in design and production, as it improves interaction, precision, and cost-efficiency while reducing errors through standard symbols and guidelines.

Along with develop controls, GD&T additionally includes alignment controls, such as parallelism, perpendicularity, and angularity. These symbols gauge exactly how much a function has to align with respect to an information recommendation. For example, a perpendicularity control specifies that a surface area must be at a right angle to an additional surface within a defined resistance. Such controls are crucial in settings up where accurate alignment is essential, such as mechanical elements in a transmission system. Understanding exactly how to define and interpret these alignment symbols is critical for exact production and quality engineering.

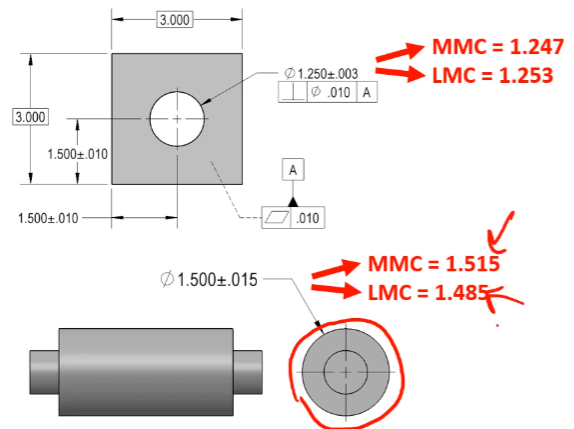

Location manages such as proportion, concentricity, and setting are likewise necessary elements of GD&T. Placing a function properly is critical in guaranteeing that parts can be assembled without trouble. The setting sign, as an example, ensures that openings or slots lie at defined works with within a defined tolerance zone. Concentricity is utilized to make certain that cylindrical attributes are straightened along an usual axis, which is particularly important in applications calling for rotational proportion. Learning to use these location symbols successfully will help designers in attaining practical components that fulfill style requirements while additionally streamlining the manufacturing procedures included.

Another essential element of GD&T is the concept of information, which are recommendation points or surface areas that offer as a basis for dimension. Correctly defined datums make it possible for engineers to control variations more successfully, minimizing the possibility of mistakes in production.

When a designer specifies resistances using GD&T symbols, it decreases the ambiguity commonly connected with typical dimensioning techniques. In markets where accuracy and high quality are paramount, such as aerospace or clinical device production, the function of GD&T in streamlining interaction can not be overstated.

In addition, the application of GD&T is helpful for expense effectiveness in manufacturing. By specifying resistances much more precisely, engineers can optimize styles to utilize processes and materials better. By specifying larger resistances where tight resistances are unneeded, producers can make use of less pricey machining methods, conserving both time and cash while still maintaining the stability of the final item. This efficient technique aids alleviate waste and minimizes production costs, which is vital in today’s open market. Designers that understand GD&T can substantially influence the cost-effectiveness of their designs without compromising quality or efficiency.

Several educational resources, workshops, and training programs are now offered to help developers and engineers learn the nuances of GD&T. Practical applications of GD&T in case research studies can offer understanding right into just how properly carried out symbols lead to boosted top quality and lowered scrap prices in manufacturing.

When modifying or translating design illustrations that make use of GD&T, attention to detail is extremely important. Designers have to guarantee that they recognize the ramifications of each icon and that the attracting accurately communicates the designer’s intent. Furthermore, keeping a consistent approach to GD&T symbols within an organization is vital. Having a standard set of guidelines for just how GD&T is used in design files can avoid misunderstandings and mistakes throughout departments. Standardization promotes a society of quality and consistency, strengthening the relevance of GD&T concepts in day-to-day design technique.

Discover mmb vs mmc the significance of Geometric Dimensioning and Tolerancing (GD&T) in design and manufacturing, as it enhances interaction, accuracy, and cost-efficiency while minimizing errors via standardized symbols and guidelines.

In final thought, understanding GD&T symbols and guidelines is an important skill for contemporary engineers, particularly those entailed in design and production. By spending in correct training and practicing the efficient application of GD&T concepts, engineers can utilize this powerful device to drive technology and excellence in their designs, eventually leading to an extra effective and affordable item growth lifecycle.